Production > STEEL > Technology

STEEL PRODUCTION PROCESS

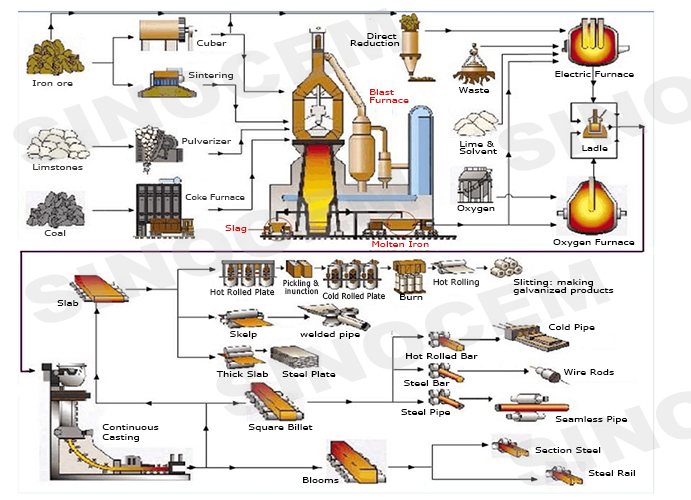

The manufacture process of steel includes 4 stages: iron-making, steel-making, casting steel and steel rolling.

1. Iron-making

There are 4 kinds of iron ore: magnetite Fe3O4, hematite Fe2O3, limonite 2Fe2O3.H2O, and siderite FeCO3. Iron ore after crushing, dressing, washing, becomes iron concentrate or ore fine, and become the main material in smelting iron. Iron concentrate, ore fine, coke and solvent after sintering, are fed into blast furnace where they are heat to about 1500 degree, melting the iron to become molten iron, CO produced from unburnt becomes reducer, to restore iron from the molten iron. Molten iron is the main material in steel-making.

2. Steel-Making

Steel making is a process of melting, refining, and alloying pig iron under a high temperature. The main part in refining process is to remove carbon, silicon, manganese, phosphorous and other impurities.

There are two types of steel refining furnace: rotating furnace and electric arc furnace. Rotating furnace used to melting the molten iron from the blast furnace and scrap, electric arc furnace used to re-melt the scrap steel.

3. Casting Steel

There are two types of steel refining furnace: rotating furnace and electric arc furnace. Rotating furnace used to melting the molten iron from the blast furnace and scrap, electric arc furnace used to re-melt the scrap steel.

Before molten steel being rolled or formed into finished products, it has to solidify and be formed into standard, semi-finished casting products which are avalable in basic shape called billets, blooms or slabs. Casting steel includes ingot casting and contiuous casting. Continuous casting is now the most mordern technology, which pours molten metal directly into a casting machine to produce billets, blooms or slabs.

4. Steel Rolling

Steel ingots and continuous casting slabs from casting, are put into middle of the rotation roller, through which to be continuously spreading, rolling and formed into different finished steel products.

We manufacture and export quality steel products, such as: rebars, wirerods, steel plates, profile steels, etc, with high strength and high tenacity.